Description

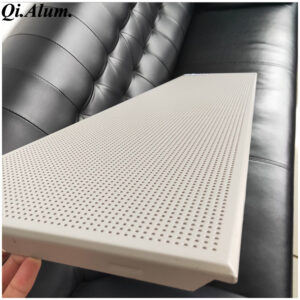

erforated Metal – Material & Coating Information

ANODISING ALUMINIUM

Anodising aluminium provides the sheet with enhanced protection against corrosion, however the anodising process does not ‘cover up’ the parent material, hence any surface blemishes, scratches or inconsistencies in the supplied aluminum are still visible. This may also cause colour variation between panels. Where possible, Locker Group will ensure project materials are sourced from the same mill, and extra care is taken to prevent scratching. However even this extra care can not guarantee a blemish free product without colour variation.

ELECTRO-POLISHING

recommends electro-polishing whenever Stainless Steel material is specified for an external project.

FERROUS METALS

does not recommend that ferrous based products be installed in external applications, therefore there is no warranty offered against corrosion.

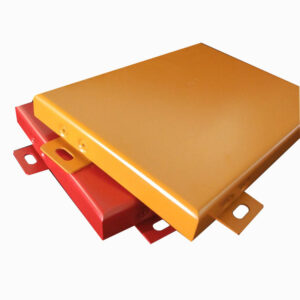

POWDER COATING

recommends powder coating colours are selected from the Duratec range for maximum protection. Please refer to the Dulux website for more information.

HOT DIPPED GALVANISING

Zinc metal used in the galvanising process provides an impervious barrier between the steel substrate and corrosive elements in the atmosphere. It does not allow moisture and corrosive chlorides and sulphides to attack the steel. Zinc is more importantly anodic to steel – meaning it will corrode before the steel, until the zinc is entirely consumed.

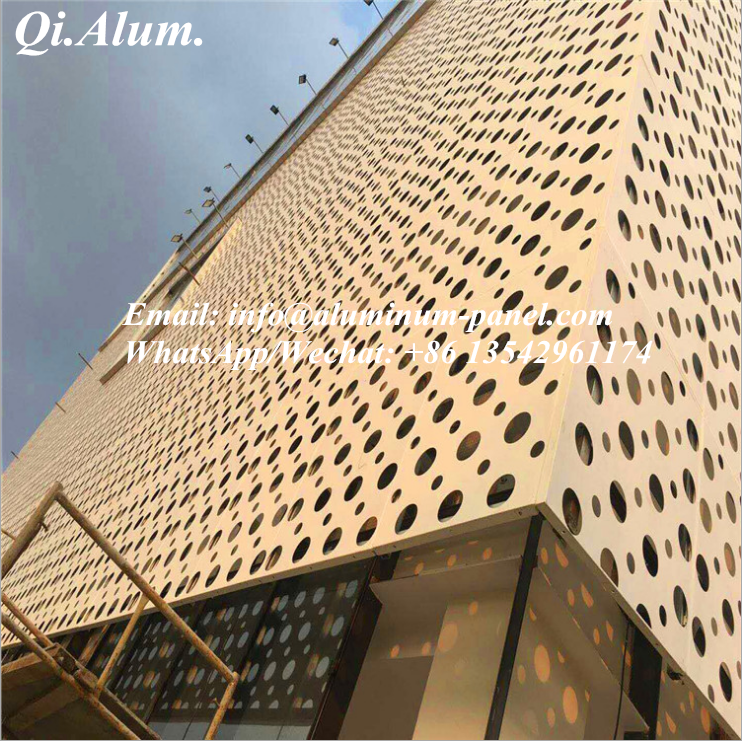

Properties of aluminum aluminum panel products:

light weight, good rigidity, high strength, reasonable structure. Resistance to wind pressure deformation, rain leakage and resistance,

Air leakage and seismic performance can meet structural design requirements.

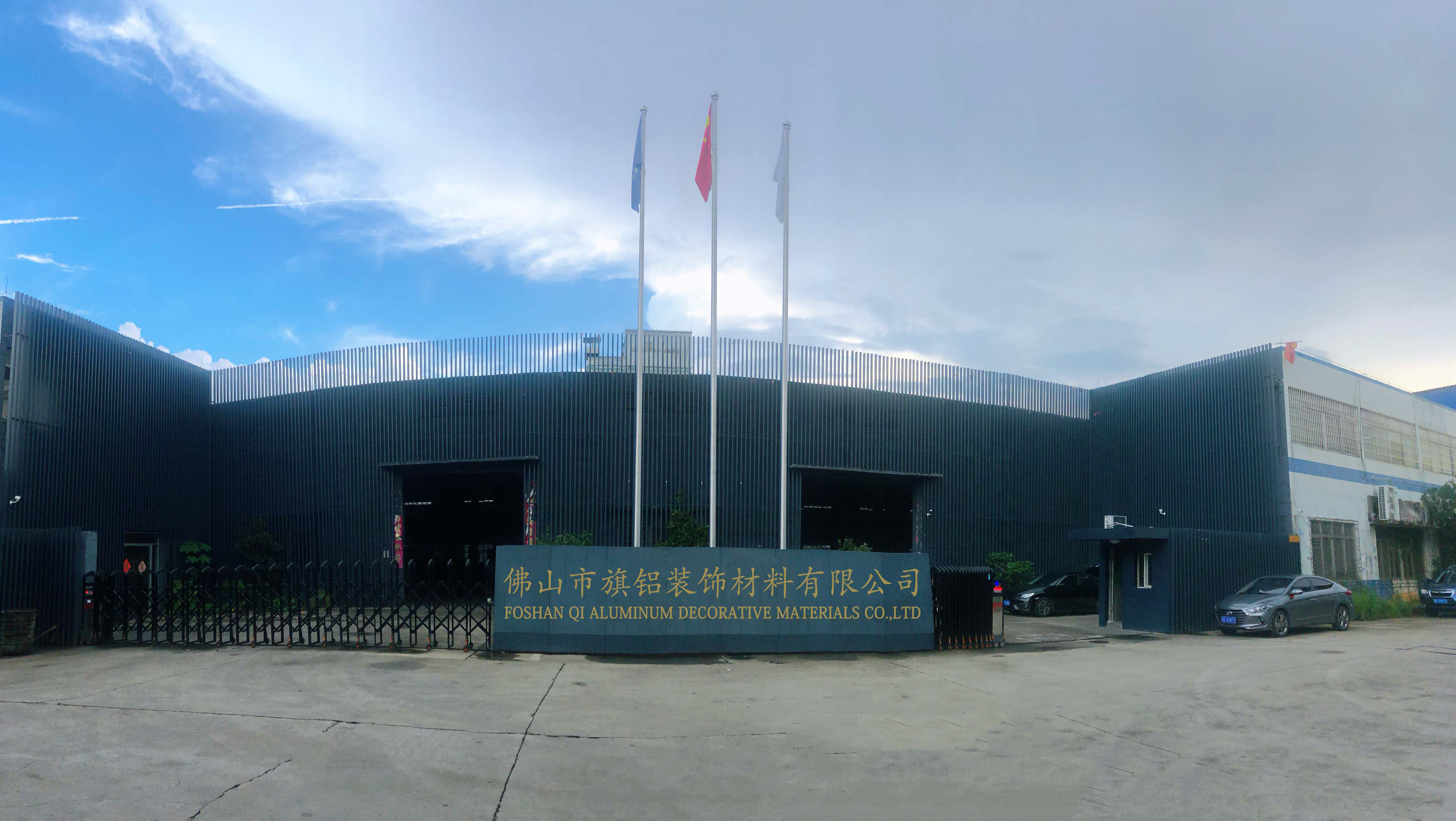

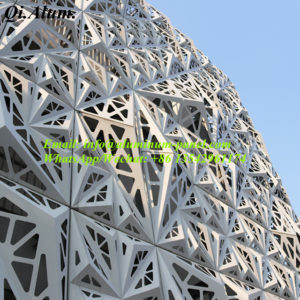

About us

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience ,We are manufacturer of fabricating aluminum perforated sheets , aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our factory production line includes 14 CNC carving/cutting machines, 8 mould punching machines with 120 sets moulds for hole punching, 9 CNC bending machines as well as accessories assembly machines. We have two coating lines with powder coating, and PVDF coating with working 24*7 hours, cooperating with Jotun, PPG, Akzon brands . We had done projects in Dubai, Qatar, Bahrain, Kuwait, Tajikistan, Tanzania, Maritius, Singapore, Malaysia, Australia, Canada, America and so on. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design ,fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price , globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!