Description

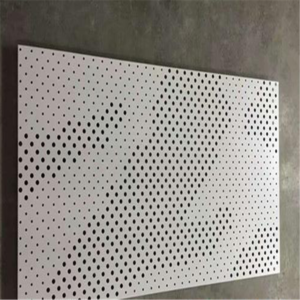

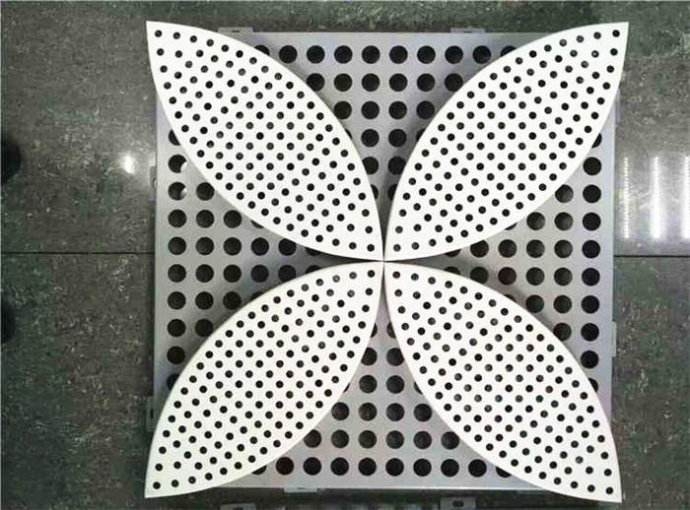

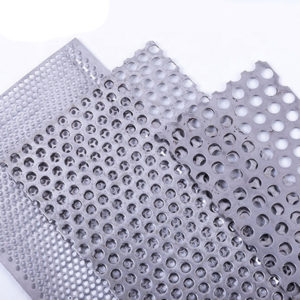

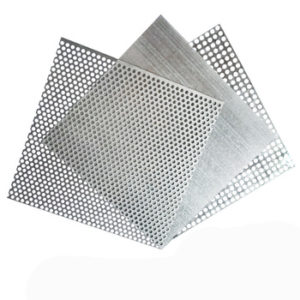

AA1100 Material Aluminum Fire rated Perforated Panel Aluminum Curtain Wall AA1060 Material Panel Manufacturer

| Product specifications | |

| Thickness of Aluminum Plate on Face/Bottom: | 0.12 mm, 0.18 mm, 0.3 mm, 0.4 mm, 0.5 mm

(customizable in the range of 0.1-0.5 mm) |

| Length (mm): | Standard length 2440 mm(can be specified by customer) |

| Width (mm): | Conventional 1220 mm, 1250 mm, 1500 mm

(can be customized, not more than 1600 mm) |

| Thickness (mm): | Conventional 3mm, 4mm (customized within 1.5-6mm) |

| Standard size: | 1,220 x 2,440 mm

(special size can be made according to customer requirements) |

Product Characteristics:

1 High Peeling Strength

ALUTILE Panel is cross linking under high temperature with high-performance and molecular binding materials, which reaches the best level for the important feature high peeling strength

2 Superior Weather Resistance

By mean of KYNAR500 based PVDF coating resin, ALUTILE panel possesses some superiorities in corrosion resistance, alkali resistance, chalking resistance of ultraviolet light. When exposed to the heat of tropical sunshine or the cold of frigid snowstorm, the panel never loses its colorful appearance.

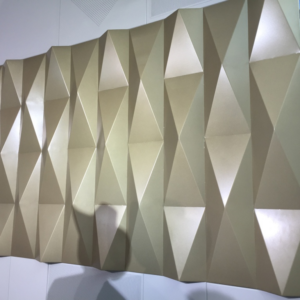

3 Light Weigh and Easy to process

ALUTILE Panel is easy to process for its light weight (3.5-5.6kg/m2) which can decrease the loss during an earthquake. The processing such as cutting, planning, bending or arc and several configurations in right angle can be done by some simple woodworking tools. Designers can also make the flexibility in the panel. The installation work is going to be easy and fast. For this reason, it can save the cost.

4 Excellent Fireproof Property

Its core layer is manufactured with Anti-toxic polyethylene core materials, having the combustion resistance property. Two surface layers are made of aluminum, which is difficult to be burnt. Therefore, this is a kind of safe fireproofing materials, complying with the fireproof demand in building code.

5 Coating Evenness, Multiple Colors

Since applied the chemosynthesis treatment and Henkel technology, the adhesion between the paint and panel becomes evener, having multiple colors. There is more space for your choice to the color with individuality

6 Easy to Maintain

The anti-contaminant property has been obviously improved for ALUTILE aluminum composite panel. Due to good self-cleaning capability, neutral detergent can clean the panel easily even though the pollution is very serious.

7 Impact Resistance

The impact resistance and toughness are strong. The coating layer can not be crashed when it is bent. The panel can not be damaged when in a strong windy and sandy condition.

Making Process

1. First cut the (pre galvanized) iron tube(round or square) into the required length.

2. Use the mould to fix the cut tube then weld the rail and pickets. there are two welding methods :

A. full welding B.point welding

The workers first use the small polish machine to polish the welding points one by one .

3. After finished all the welding ,using the big polish machine (steel sand ) to wash the oil .

4. Then make the whole fence to do the chromium plated .

5. Fianlly to do the powder coating .

FAQs

Q1. What are your terms of packing?

We pack our goods in box,fumigation free plywood boxes are suggested for shipping container.

Q2. What is your terms of payment?

We can accept L/C,D/P at sight or 30,60,90 days are also accepted.

Q3. What are your terms of delivery?

A: The terms are EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: it will take 15 to 25 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes. we can produce by your samples or technical drawings.

Q6. What is your sample policy?

samples are free and shipping cost of sample is required to pay in advance or collect.

Q7. Do you test all your goods before delivery?

We have Q/C &Q/A for the best quality of our goods.