Description

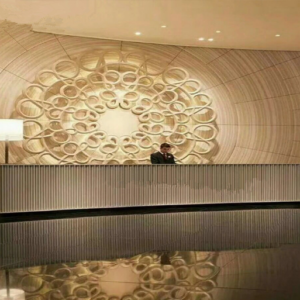

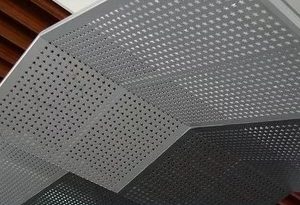

AA1050 Mill Finish Aluminum Wall Cladding Decorative Panel

Product Description

| 1.Our products strictly start with material selection procedure, and go through a rigorous examination by our staffs who are expert in quality management.

2.AS2047 certification—— One of the highest standard of the industry. 3.Patented design aluminum profile , many of the humanized design points. |

|

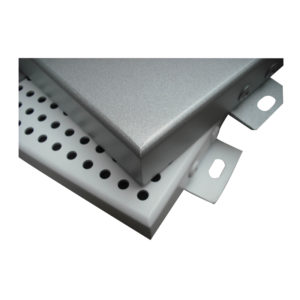

| Profiles | 1.Thermal break aluminium profiles 2.Aluminium alloy profiles 3.1.4~2.0mm aluminum profile thinness |

| Thickness | 1.5mm, 2.0mm, 2.5mm, 3.0mm, 3.5mm, 4.0mm, 5.0mm, 8mm, 10mm, 20mm. Other thickness are available on request |

| Finish | 1.Powder coating 2.Anodized 3.Electrophoresis 4.Wood grain |

| Types | Awning window, Sliding window, Bifold window Casement window, Tilt and turn window, Fixed window, Shutter window Sliding door, Hinge door, Bifold door Lift and sliding door, Pivot door, Escape door Sensor door, Glass louvre, Aluminim louver |

Surface treatment:

The Surface is coated with PVDF fluorocarbon after chromium treatment, and PVDF paint brand options include PPG, Akzo Nobel, Nippon, Tiger and KCC etc. In our factory, we have approximately 100 colors for your choice and we can match the color according to your preference.

Spraying Painting Process:

1) As per AAMA2605-98 stipulated by American Architecture Manufacture Association.

2) Pretreatment of aluminum and aluminum alloy:

Degrease→Alkaline etch→Roughen(pickling)→Chromizing→Baking

3) PVDF spray painting: Workpiece loading→Primer painting→Top coat painting→Finish painting→Curing→Work piece unloading→Inspection→packing