Description

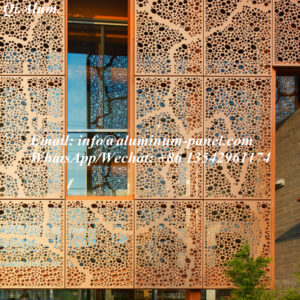

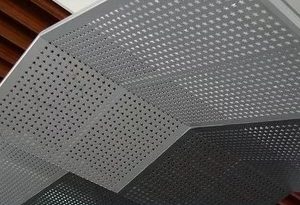

Construction Projects Aluminum Perforated Decorative Panel

Description

| Aluminum alloy | 1100, 3003, 5005, 5052 |

| Panel thickness | 2.0~5.0mm or customized thickness |

| Dimension | Width: up to 2200mm Length: up to 6000mm |

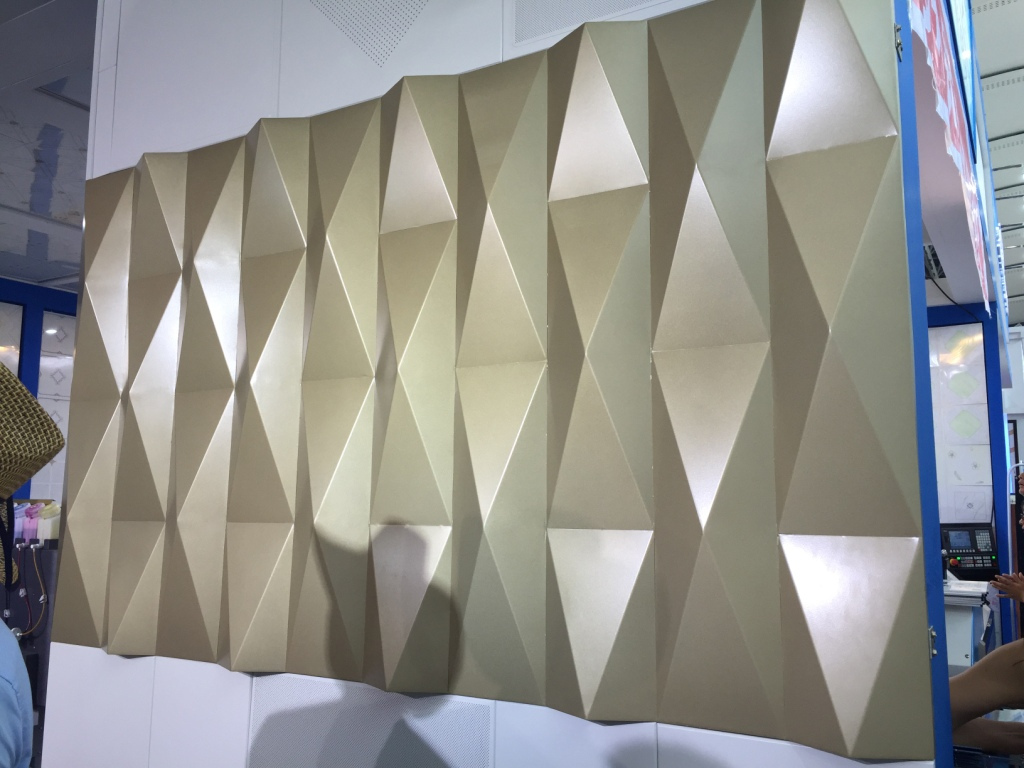

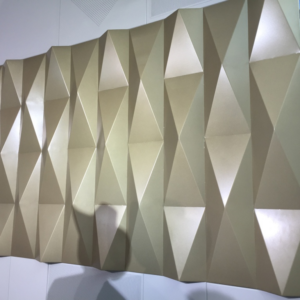

| Surface treatment | PVDF 2/3/4 Layer coating (AkzoNobel/PPG) powder coating (Powder/fluorocarbon powder) Woodgrain (wood grain paper/thermal transfer printing/wood grain painting) Rock grain (rock grain painting/thermal transfer printing) |

| Color | Pure color, Metallic color, RAL color, Pantone color. |

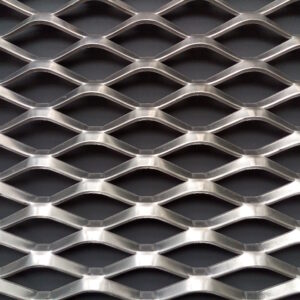

| Shape | Flat, Cambered, double curved, triple curved, spherical, customized shaped. |

| Warranty | Max 25 years guarantee for the ideal application environment |

*Scopes of Application

1) Aluminum façade, Aluminum Cladding, Exterior Wall Decoration.

2) Interior Wall Decoration, Column cladding

3) Passageway, elevator, shopfront decoration, advertisement boards.

4) Ceiling and so on.

5) With complicated shape such as pagoda, difficult to get dirt, easy for maintenance and caring.;

6) Wide color selection, ultra good decoration effect;

7) Easy to be recycled, with no pollution, good for sustainable development and saving the earth.

Process

Impact test: coating adhesion test.

Hundred grid test: coating adhesion test, after coating is completely dry, 3M gummed paper in painting has hundreds grid ink surface, 45 degrees quickly pulled off.

Coating thickness test: Ensure average coating thickness match to KYNAR 500 standard.

Chromatic aberration test: with the colorimeter to ensure the color of mass production panel match with GB standard.

Glossiness test: Gloss is a measure of how reflective a material is at a specified angle based on the refractive index.