Description

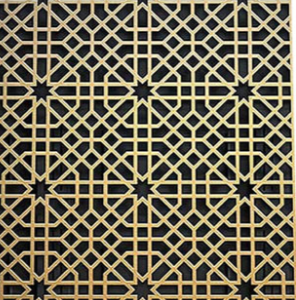

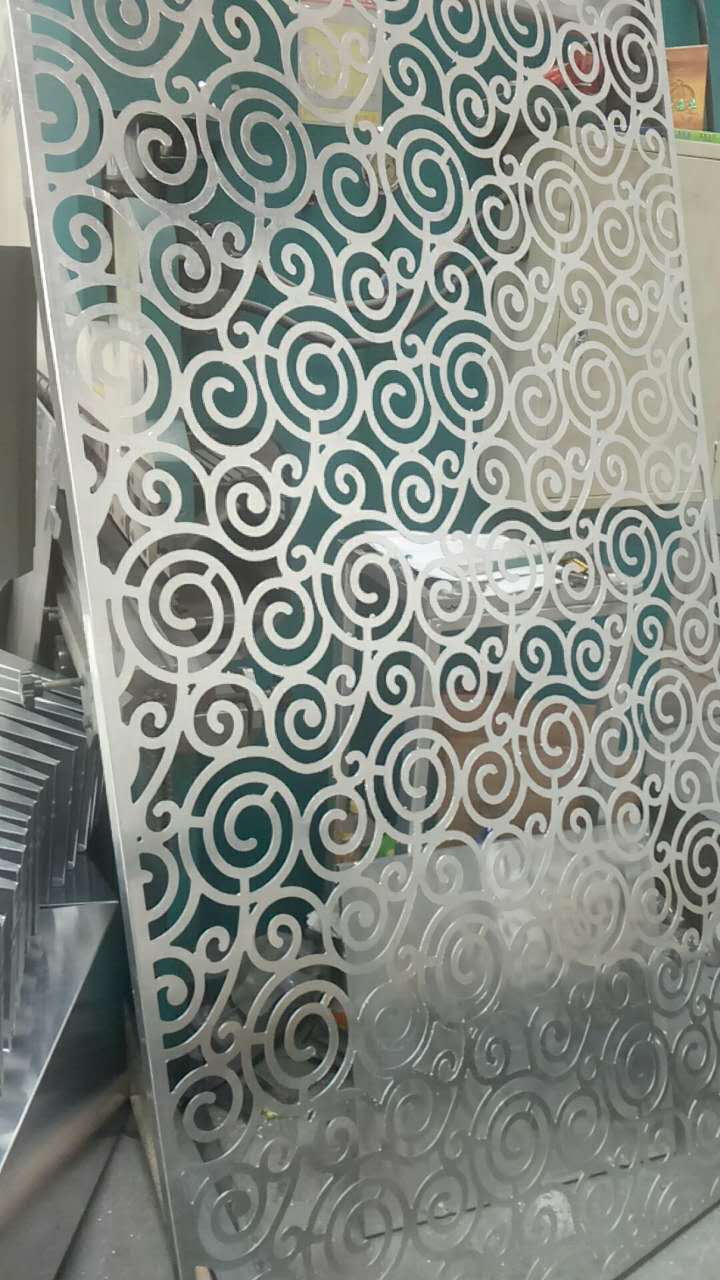

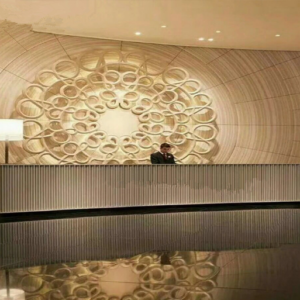

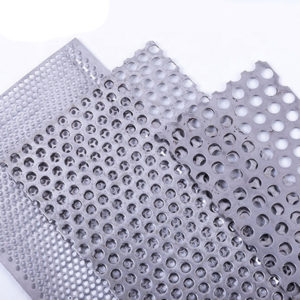

AA1100 Material Aluminum Engraved Perforated Sheets For Wall Cladding Decoration

Product Description

| Materials | Al 1100/3003 |

| Thickness | 0.3/0.4/0.5/0.6/0.8/1.0/1.2/1.5/1.2/1.3/1.5/ 3.0/3.5/4.0/4.5/5.0 or other customized |

| Size | Customized |

| Surface Finished | Powder Coating, Brushing, Polishing, Anodizing,PVDF coating, PE coating |

| Processing | Laser,CNC-cutting |

| Surface Roughness | Customer |

| Cutting Mode | Laser, CNC, Shearing |

| Certificate | ISO9001:2015 |

Excellent performance of Engraved Perforated Sheets:

1, excellent weather resistance and UV resistance, the color is very durable and stable, can maintain 10 or even 30 years without discoloration;

2, excellent acid resistance, high alkali performance, can withstand the harsh environment of the wind and sun;

3, good adhesion, high toughness, strong impact resistance, smooth coating, strong pollution resistance, easy to clean;

4, a wide range of colors, bright and beautiful, good texture, there are monochrome paint, metal paint can be;

Our company

Foshan Qi Aluminum Decorative Material Co., Ltd was built in 2008, which is a professional manufacture of wire mesh, including expanded metal, perforated metal sheet and antiskid safety grating. We have advanced technology, manufacturing excellence, excellent business process, and the quality of products have reached national standards and testing standards of all kinds of industries. We hope that we can establish and keep a closer trade relationship with domestic and foreign customers on the basis of the mutually beneficial and friendly cooperation. Please feel free to contact with us.

Customized Designs And Size

1. Customized designs and size can be fabricated as per our clients’ request.

2. Sample can be delivered for approval prior to mass production.

Quality Control Every STEP

1. Every step of production is followed up by our team and respond to client by photos.

2. Quality control is carried out before packing and loading.

Accept OEM Production

1. JANZU accept OEM production to meet your project standards.

2. Most advanced molding equipment and professional computer designing.